Brass strip and semi-finished products manufacturer from Germany

We offer ribbons in 3 different brass alloys.

Strip product: Buy brass strip and semi-finished products from Germany

Applications of brass alloys MB30 | MB36 | MB37

Typical applications

- Jewellery

- Metalware

- Semiconductor carriers

- Building facades

- Deep drawn parts

- Stamped and bent parts

- Connectors

Copper-base-alloys

Available dimensions of brass strip

- Bright pre-rolled strip

1,0 – 5,0 mm - Precisions strip thicknessess

0,07 – 1,2 mm - Strip widths

3,0 – 600 mm,

but at least 10 times strip thickness

Brass alloys MB30 | MB36 | MB37

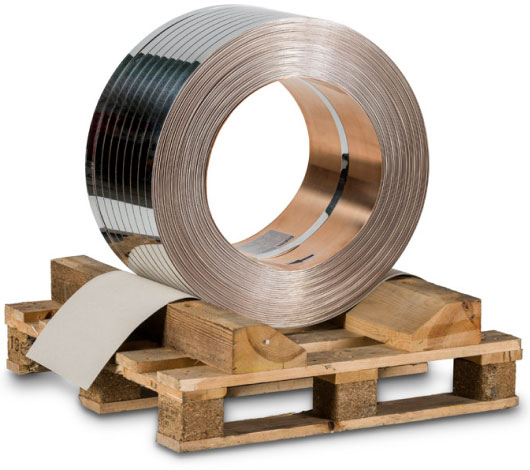

Brass strip in various delivery presentations directly from Sundwiger Messingwerk

The delivery form of our products depends on the technical facilities of our customers. Three basic designs are available here. These are each adapted to the equipment available at our customers.

The most used form are coils. Here, the individual coils are stacked on pallets, usually separated by spacers.

In the spooled version, several coils are wound in one spool. The coils are connected with help of a weld seam. In this way, set-up times can be saved in the subsequent process steps.

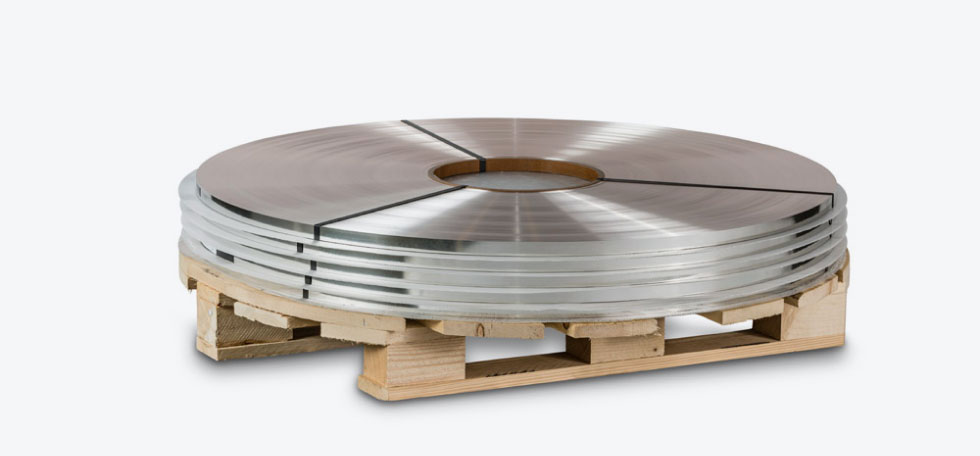

Multiple Pancake

Multiple pancake is a special form of coil design. Here, the individual coils are connected alternately at the inner and outer windings by weld seams. The created “endless strip” can be unwound directly from the pallet on turntables.

Brass strip FAQ: Frequently asked questions about our brass alloys

What are the special features of the materials MB30 | MB36 | MB37?

MB30 is a brass alloy with a fine lustre, particularly good cold formability and suitable for surface coating. Among the copper-zinc alloys, MB30 is characterised by very high electrical and thermal conductivity and has a medium modulus of elasticity and average strengths. The colour of MB30 is yellow due to the increasing zinc content. Typical applications are connectors and cups. MB30 is a single-phase copper alloy and is available in annealing grades that allow exceptionally good cold-workability and deep-drawing properties with no spike formation. This alloy is registered with U.S. EPA as an*microbial and with the consideration of Pb and Cd it meets the requirements of OEKO-TEX Standard 100.

MB36 is a brass alloy with a fine lustre, good cold formability and suitable for surface coating. Among the copper-zinc alloys, MB36 is characterised by very high electrical and thermal conductivity and has a medium modulus of elasticity and average strengths. The colour of MB36 is already deep yellow due to the increasing zinc content. Typical applications are connectors and cups. MB36 is a single-phase copper alloy and is available in annealing grades that allow exceptionally good cold formability and deep-drawing properties without tip formation. Taking into account Pb and Cd, MB36 meets the requirements of OEKOTEX Standard 100.

MB37 is a brass alloy with a fine lustre, good cold formability and suitable for surface coating. Among the copper-zinc alloys, MB37 is characterised by very high electrical and thermal conductivity and has a medium modulus of elasticity and average strengths. The colour of MB37 is already deep yellow due to the increasing zinc content. Typical applications are connectors and cups. Taking into account Pb and Cd, MB37 meets the requirements of OEKOTEX Standard 100.

Material designations of MB30 | MB36 | MB37

| Material designations | |||

| Sundwiger | MB30 | MB36 | MB37 |

| DIN-EN Symbol | CuZn30 | CuZn36 | CuZn37 |

| DIN-EN | CW505L | CW507L | CW508L |

| UNS | C26000 | C27000 | C27200 |

| JIS | C2600 | C2700 | C2720 |

Nominal composition of MB30 | MB36 | MB37

| Nominal composition (Mass in %) | |||

| Sundwiger | MB30 | MB36 | MB37 |

| Cu | Balance | Balance | Balance |

| Sn | < 0,05 | < 0,05 | < 0,05 |

| Zn | 30 | 36 | 37 |

| Ni | < 0,2 | < 0,2 | < 0,2 |

| Fe | < 0,05 | < 0,05 | < 0,05 |

| Al | < 0,02 | < 0,02 | < 0,02 |

| Pb | < 0,005 | < 0,005 | < 0,005 |

| Other | < 0,1 | < 0,1 | < 0,1 |

Processing instructions of MB30 | MB36 | MB37

| Processing instructions | |

| Cold forming properties | very good |

| Machinability | satisfactory |

| Electroplating properties | very good |

| Hot-dip tinning properties | very good |

| Soldering | very good |

| Resistance welding | good |

| Gas shielded arc welding | satisfactory |

| Laser welding | sufficient |

Physical properties of MB30 | MB36 | MB37

| Physical properties (at room temperature) | ||||

| Sundwiger | MB30 | MB36 | MB37 | |

| Electrical conductivity soft | 15,7 | 14,5 | 14,5 | MS/m |

| Thermal conductivity | 124 | 120 | 120 | W/(m*K) |

| Thermal expansion coefficient between 20 and 300 °C | 19,6 | 20,2 | 20,2 | 10-6/K |

| Density | 8,5 | 8,4 | 8,4 | g/cm³ |

| Modulus of elasticity | 115 | 110 | 110 | GPa = kN/mm² |

We advise you on our brass strip copper base alloys

Call us or write to us, we will be happy to advise you personally!

Contact Form

Write to us, we would be happy to advise you personally!