About us

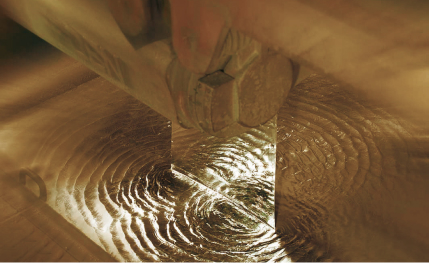

Non-ferrous Metal – our passion

More than 325 years ago, people in Sundwig began forging the brass sheets needed for thimble, tobacco can and wire production on water-driven plate hammers. Later, the rolling mill replaced the hammer, the steam engine and finally the electric motor replaced the water wheel.

Today, the experience gained over the centuries in the production and processing of non-ferrous metals forms the foundation for the production of more than 40 high-quality alloys.

With 8 casting lines, 3 rolling mills and corresponding annealing capacities, we have the necessary flexibility to meet the ever-increasing customer requirements in terms of physical and mechanical properties as well as product quality.

Locations: Germany | China

Years of experience

Casters

Roll Stands

Future-oriented materials for strips and wires made of copper alloys

Depending on the alloy selected, the highest requirements are fulfilled in terms of strength, formability and punchability, but also thermal and electrical conductivity.

In the wire sector, the product portfolio is additionally completed by copper. For us, the quality and reliability of our materials are always the focus.

Due to the range of possible applications, our products are represented in almost all industries.

The main applications are in the following areas:

- Automotive industry

- Electrical Industry

- Telecommunications

- White goods

- Consumer electronics

- Railway applications

Milestones of the Sundwiger Messingwerks

1698

Foundation of the family company Johann von Becker

1739

1864

1958

Diehl-Metall takes over Sundwiger Messingwerk

1964/73

1979/83

Change of the entire production to 600 mm coil width

1999

2000

2004/06

2007

Re-design of hot-dip tinningline

2016

Modernisation of the four-high-rolling mill / Roller changing device

2018

Modernisation of the 20-roll cold rolling mill / electronic control system

2020

Our Locations

Management

Management

Mediumsized traditional company

The reputation of Sundwiger Messingwerk among its customers as a successful, traditional medium-sized company is based to a particular extent on the high quality and compatibility of its products and services. Continuous improvement is therefore a key corporate objective. This is the basis for our legal independence and our future viability. We want to be a long-term preferred partner for our customers with a very high degree of customer satisfaction and with the quality, environmental compatibility and reliability of our products and services. We see our suppliers as an essential part of our value chains and actively integrate them into our quality and environmental management. It goes without saying that our quality and environmental standards also apply to all employees; we ensure this through regular, adequate training, instruction and audits. In addition, our operational processes are continuously reviewed and improved with regard to potential health riks for our employees. Every manager understands work safety, health management, environmental protection and quality as a management task and acts in accordance with these guidelines and the relevant regulations. By using ecological and economical technologies, we protect resources and avoid environmental impacts. To this purpose, we regularly measure and analyse our processes on the basis of defined key figures with regard to quality, environment and energy. Our products are characterised by ecological harmlessness and sustainability. We think it is very important that a high level of the raw materials from which our products are made comes from recycling.

Quality management

Integrated management system

It is important to us to perfectly realise the requirements of our customers. That is why we work every day to improve the quality of our products (and services).

As an energy-intensive company, the protection of the environment and the efficient use of energy are also central components of our corporate philosophy.

Through our integrated management system, we exploit synergies and ensure the optimisation of all processes that have an impact on quality, the environment and energy consumption.

We are certificated according to:

- DIN EN ISO 9001:2015 (quality management system)

- DIN EN ISO 14001:2015 (environmental management system)

- DIN EN ISO 50001:2018 (energy management system)

You can find the current certificates in our download area.

Environmental and energy management

Due to the location in the middle of a residential area and as a neighbour of the Sundwiger Bach stream, Sundwiger Messingwerk has a special responsibility towards its neighbours and the environment.

Investments in noise protection activities and the operate of a wastewater treatment plant, with which official limit values are significantly undercut, are just two examples of our sustainable commitment in the areas of environmental protection, occupational health and safety and energy efficiency.

Since 1999, Sundwiger Messingwerk has had a certified environmental management system according to ISO 14001 and since 2012 a certified energy management system according to ISO 50001.