Strip products

In the area of strip products, we not only offer standardised solutions, but also the possibility to individually adapting our products and their properties to specific customer requirements.

Depending on the composition, this depends on the cold forming and the annealing parameters adjusted to it.

Copper-Base-Alloys

Bronze

Dimensions

Depending on the required alloy, strip thicknesses of up to 70 µm can be realised.

- Bright pre-rolled strip

1,0 – 5,0 mm - Precisions strip thicknessess

0,07 – 1,2 mm - Strip widths

3,0 – 600 mm,

but at least 10 times strip thickness

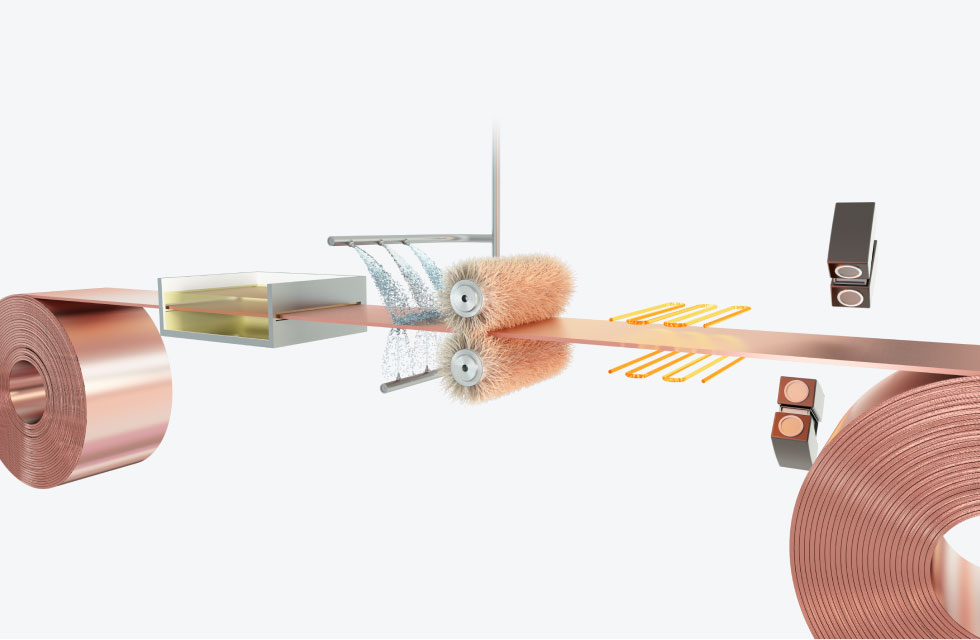

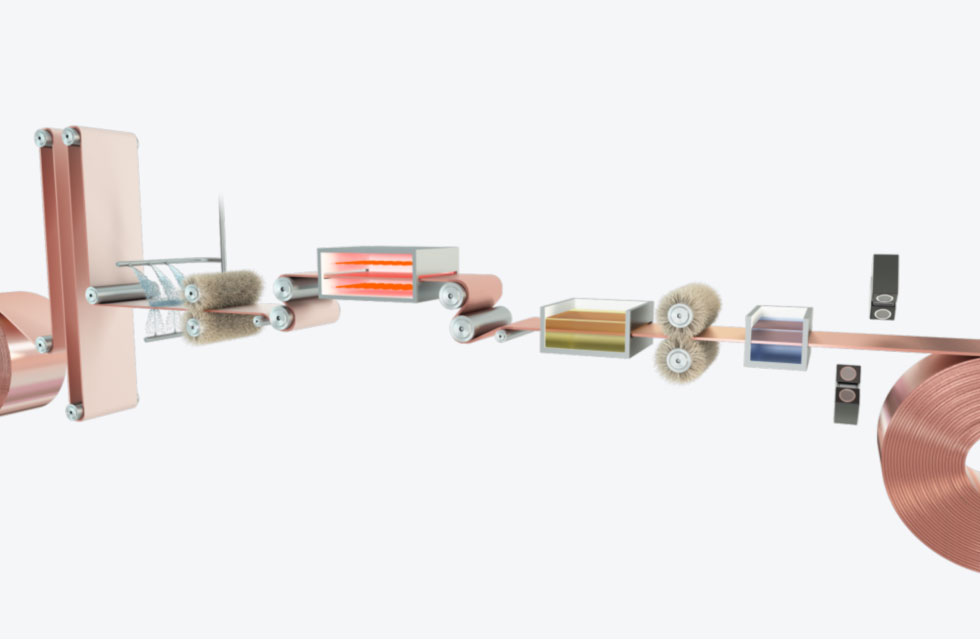

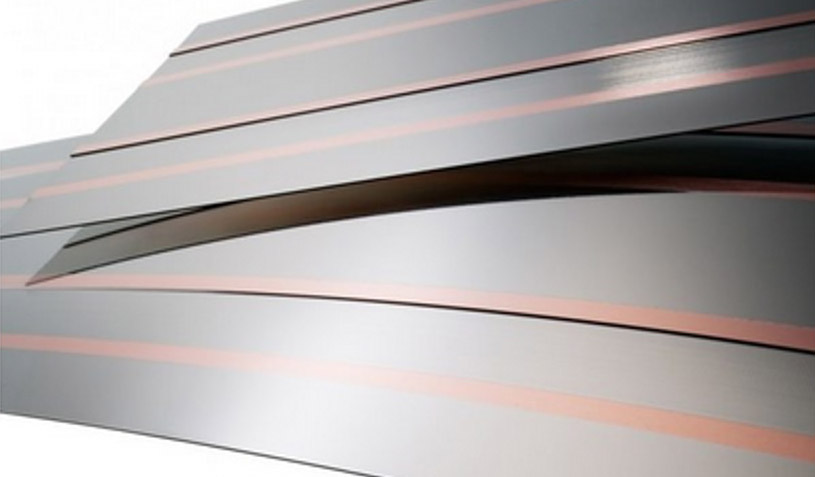

Surface

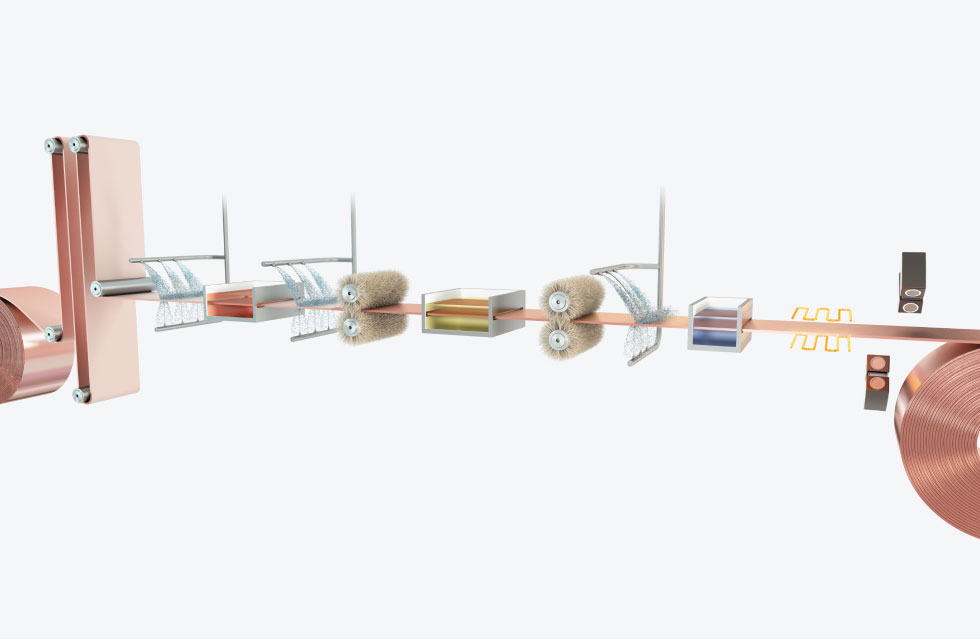

For the diversified product portfolio in the area of flat products, the Sundwiger Messingwerk also offers hot-dip tinned and electroplated surfaces in addition to the physical and technological characteristics of the basic material.

Hot-dip tinned surfaces form system- inherent intermetallic phases, thereby rendering it largely resistant to whisker formation which could lead to possible defects of electrical components.

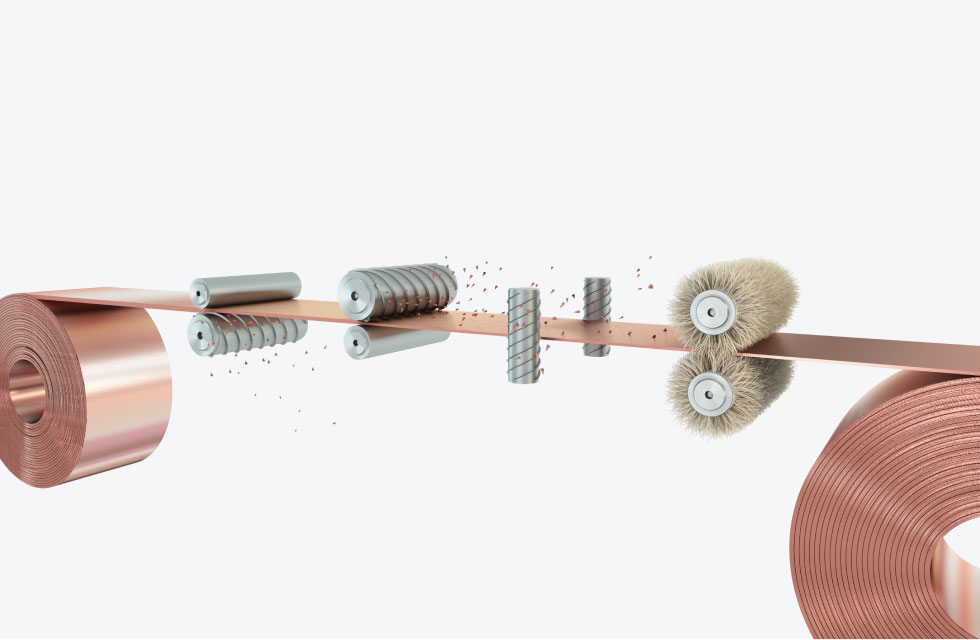

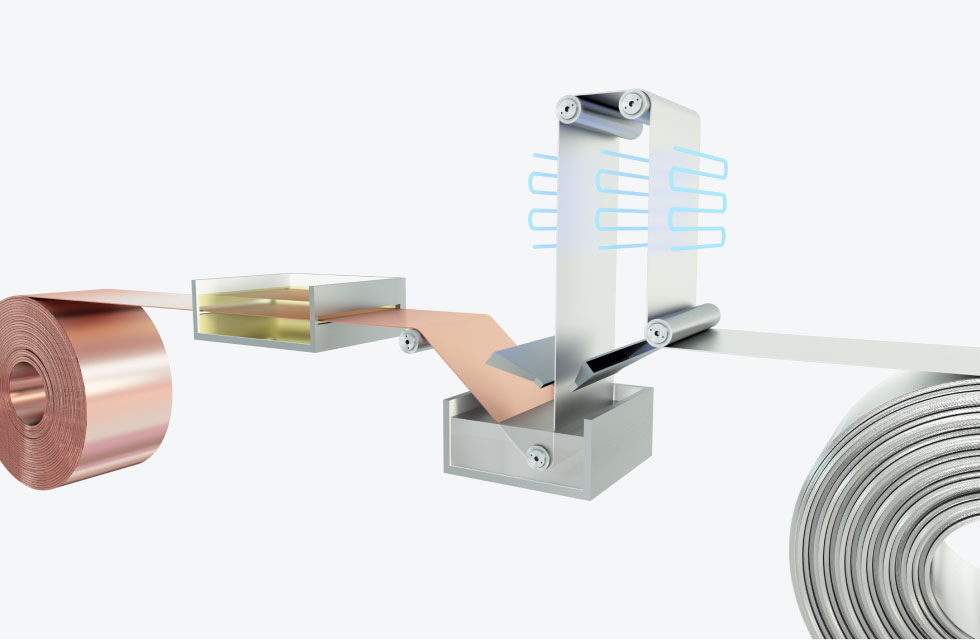

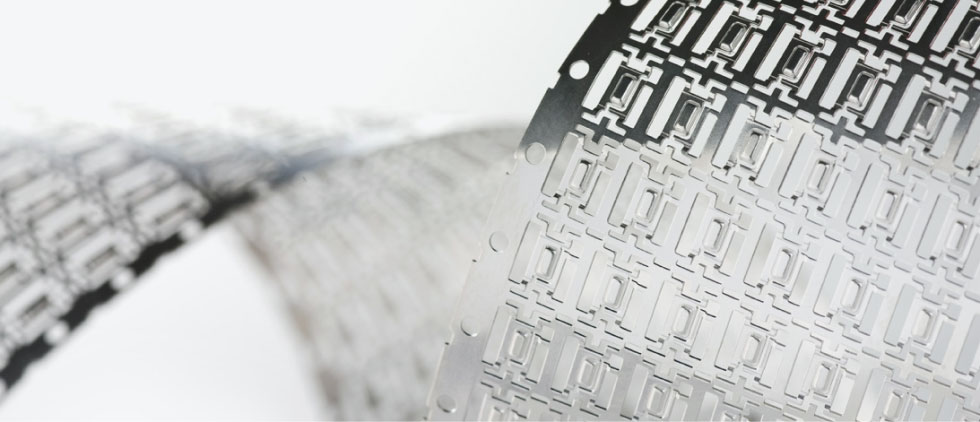

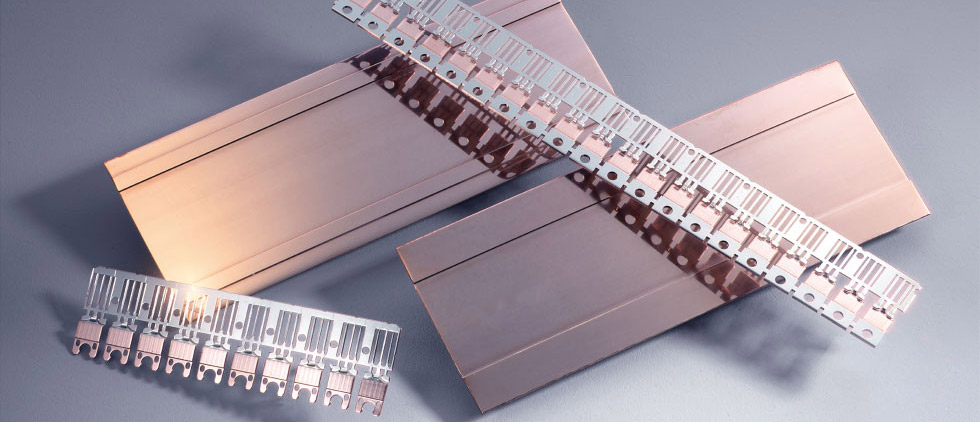

Milled strip / profiled strip

For the increasing requirements of the semiconductor industry, we supply high-precision profiled strips. These are used when different functional zones are used in a component.

- Strip widths

2,00 bis 190,0 mm - Strip thicknesses

0,20 bis 3,0 mm

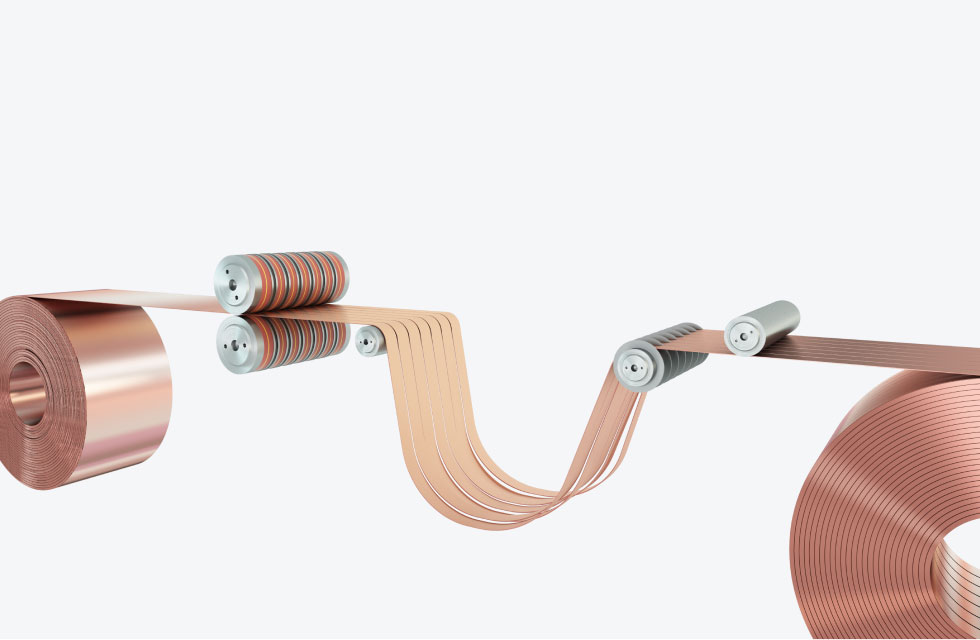

Delivery Forms

The delivery form of our products depends on the technical equipment of our customers. Three basic designs are available. These are each adapted to the equipment available at our customers.

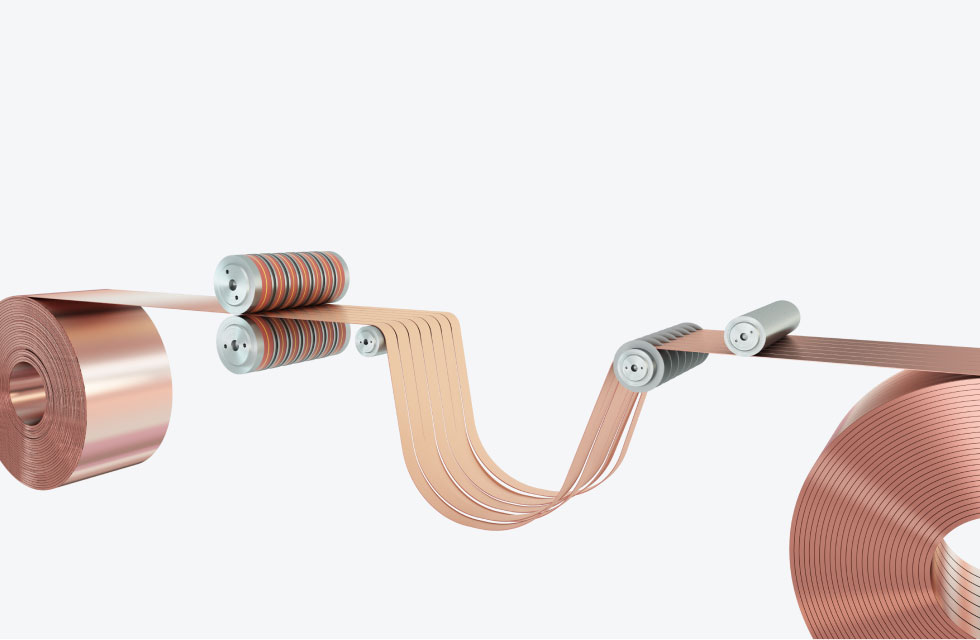

The most used form are coils. Here, the individual coils are stacked on pallets, usually separated by spacers.

In the spooled version, several coils are wound in one spool. The coils are connected with help of a weld seam. In this way, set-up times can be saved in the subsequent process steps.

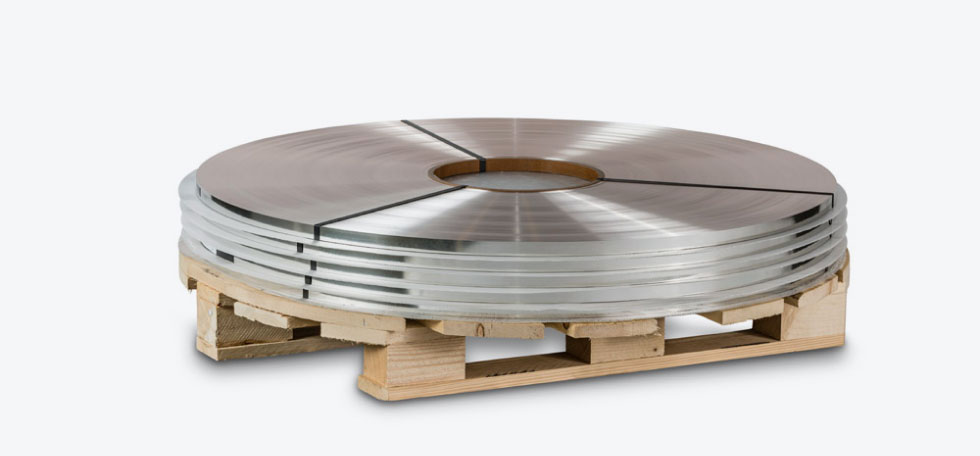

Multiple Pancake

Multiple pancake is a special form of coil design. Here, the individual coils are connected alternately at the inner and outer windings by weld seams. The created “endless strip” can be unwound directly from the pallet on turntables.

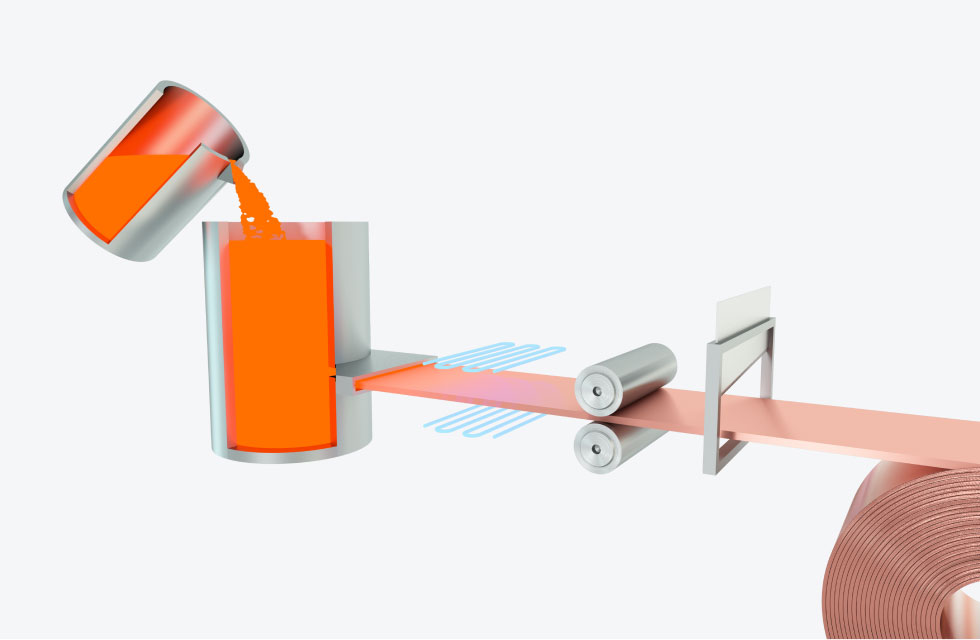

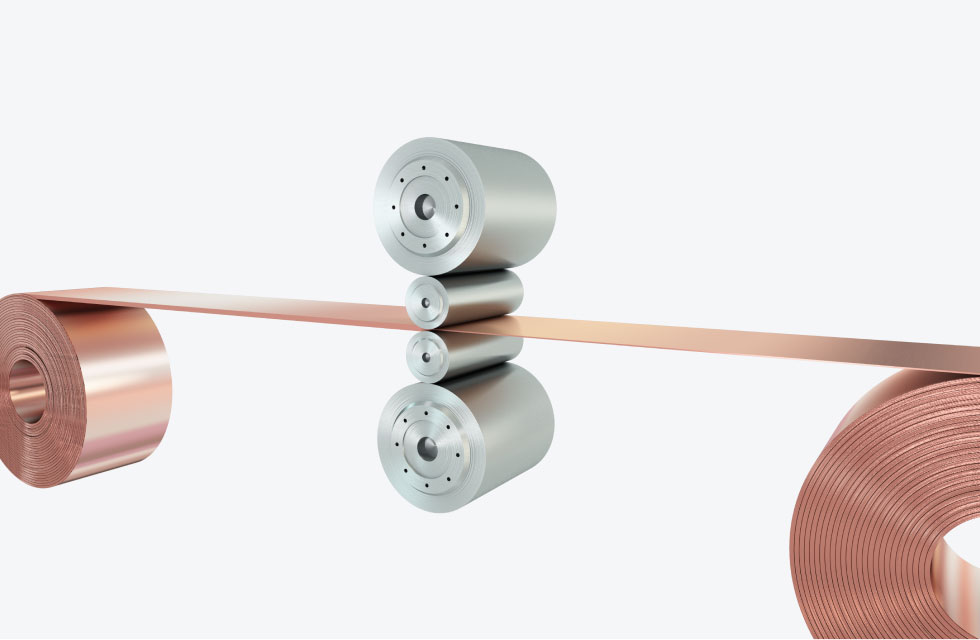

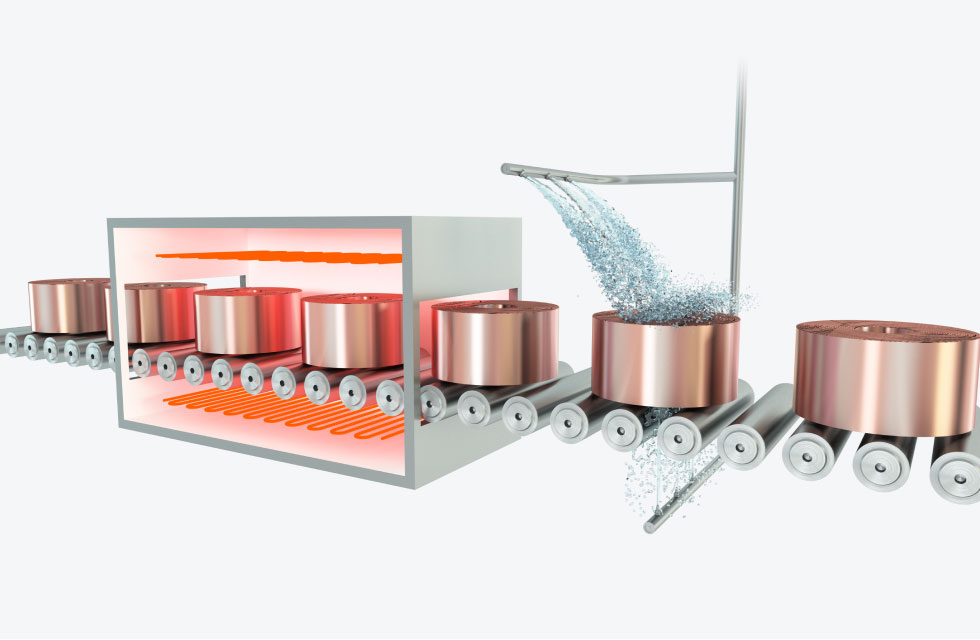

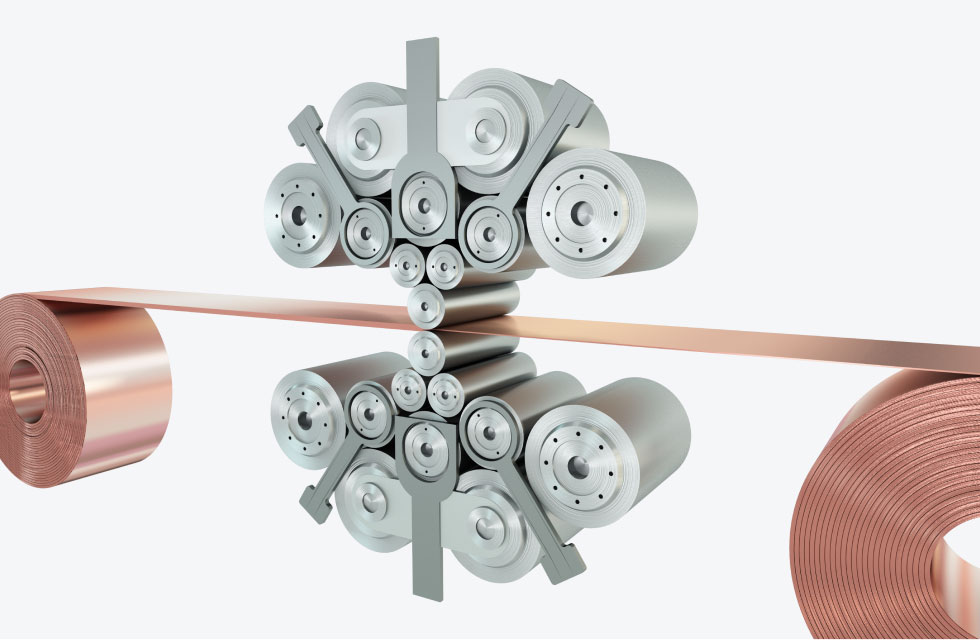

Production process

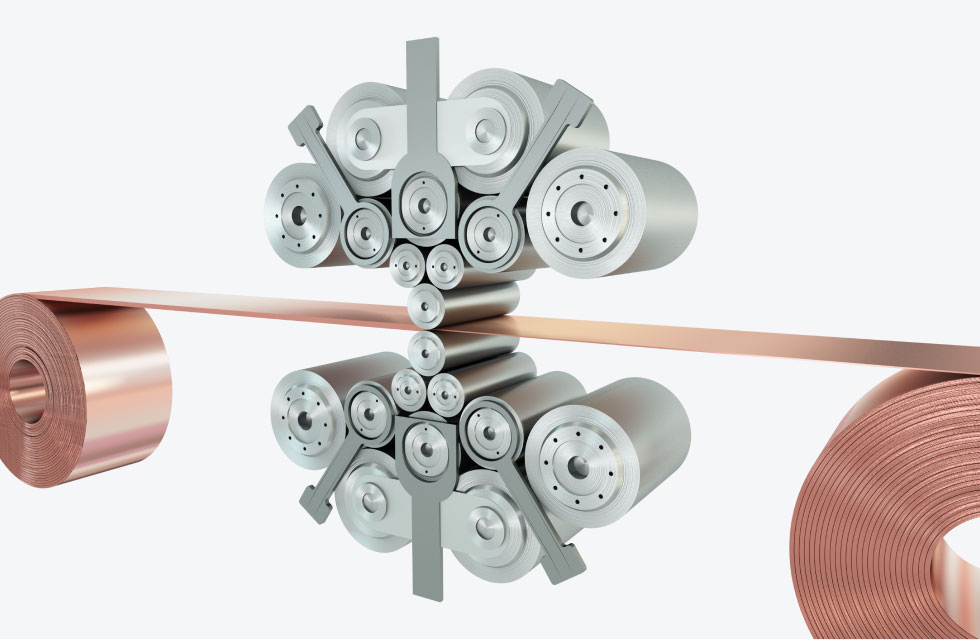

With three rolling mills, we not only have a high level of rolling capacity, but we also have the ability to guarantee even the lowest rolling tolerances within the Sundwiger fine tolerance. By using two 20-roll rolling mills, we can also offer the thinnest material thicknesses with the lowest tolerances.

Do you have questions about our products or you need a consultation?

Call us or write to us, we will be pleased to advise you personally!